Better Products Through Mechanical Variation Management

Sigmetrix’s CETOL 6σ tolerance analysis software integrates with leading CAD solutions to provide comprehensive 3D model-based tolerance analysis. CETOL 6σ provides invaluable insights to the impact of part and assembly variation using advanced mathematical solutions, enabling designers and engineers to easily address multi-dimensional problems within their native CAD environment.

Overcome your challenges with CETOL 6σ

Reduce your number of prototyping runs

Identify key contributors to product failure through simulation, before you begin your manufacturing process.

Remove human error from mistakes in calculations

Utilise precise algorithms to determine variation along ISO or ASME standards.

Reduce errors in your ISO GPS definitions on your drawings

Utilise ISO GPS symbols and notations built directly into CETOL 6σ.

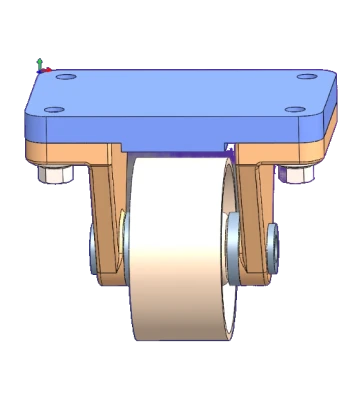

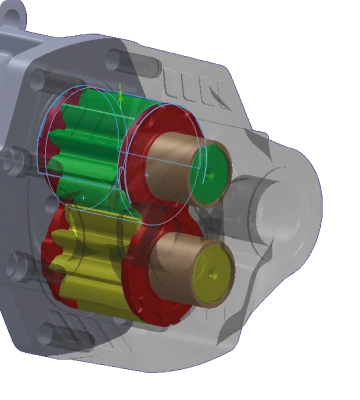

Remove the limitations of 1D stack ups through fully 3D analysis

Account for variation across complex curvatures and surface interactions.

Why CETOL 6σ?

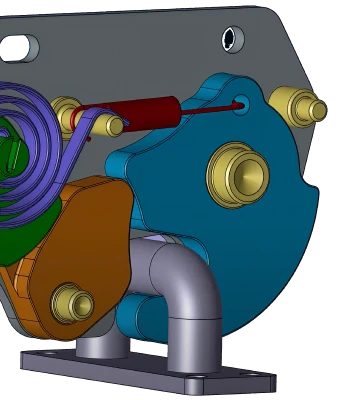

Connect to CAD

Seamlessly integrate your tolerance analysis within your SOLIDWORKS, Creo, NX and Catia design workflows.

Import existing tolerances and definitions into your analyses, and retain the link to the CAD so that tolerance improvements in CETOL 6σ get fed back into the model.

Reduce scrap rates

Root cause analysis of designs through a structured analytical process. Create savings on manufacturing costs and improve your time to market through right-first-time design.

Improve accuracy

Simulate tolerances through realistic assembly conditions

Use not only CETOL 6σ’s advanced calculations, but also its detailed modelling tools to accurately recreate the true assembly steps.

Reduce rework

Save your engineers time and energy through a structured model building approach.

Build on top of existing models to add additional analyses into one file.

Simulate Configuration Variants

Define multiple configurations for your assemblies and simulate the impact of your tolerances on all simultaneously.

Tolerance Analysis Course (CETOL 6σ).

Predict variation. Design with confidence.

Dimensional variation can undermine product performance and reliability. STRIDE’s CETOL 6σ training equips your engineers’ with advanced Computer-Aided Tolerancing skills to accurately simulate and analyse 3D tolerance stacks. By identifying and addressing variation early, your team can make informed design adjustments, reduce rework, and improve quality all while cutting costs

Related Resources

Take Control of Variation.

Book a discovery session today.